Have anyone here built a telescope dolly like these? (these are not mine)

if so, do you have any plans you can share on how you built it? is it stable enough to image from?

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

I don't have plans, I just looked at a few on the internet and made my own based on the dimensions of my mount. I am lucky as I have a small work shop I can fab and weld small project like this.

I added outriggers to aid in stability and leveling and some weight. The outriggers are setting on concrete pads pored in the dirt. My outrigger leveling screws have points ground on them and their are pointy divots in the concrete, so I align the 3 screws in the divots and then polar alinement takes less than 5 min.

Its HEAVY but solid as a rock. No issues with guiding or movement . Burrr, this picture was taken at 15 deg f last winter. Moving from my garage to this spot takes me 10 min or less.

PS, if I didn't have the ability to fab my own, and after using it for a year, I would consider buying the "Scope Buggy" I see advertised in Astronomy mag's. I think they run about $350. REALLY speeds up set up things being able to wheel it out level and PA very quickly. I leave mine on the buggy when parked in the garage. My truck sits outside lol

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

|

Ive thought about bolting casters onto a pallet in my driveway and using that as a platform lol

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Every one of the dollies shown here share a potentially fatal flaw. None of them appear to have a jack screw for lifting to dolly off of the wheels for imaging. Imaging on a wheeled dolly will almost certainly limit the quality of the results. Another potential problem is the use of wood, which isn’t mechanically very rigid. Wood can work for a small light scope but just don’t touch anything while the scope is running. Remember that at 1”, everything (even metal) is made of rubber! That means that you should use the most rigid materials possible.

You can see the roll out platform that I built for my 20” scope here:

https://www.astrobin.com/dlko5b/N/

I was concerned that this setup might ring as well, but it turned out to work really well. The entire rig weighed around 700 lbs but it took two fingers to roll it out and it provided sub-arcsecond stability. It was also extremely easy to polar align. I didn’t realized it when I designed it but the arrangement of the jack-screws provided near orthogonal polar alignment capability in altitude and azimuth. Using a PoleMaster, I could have PA done in about 5 minutes and a 70 point full sky model done 10 minutes later.

John

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

John Hayes:

Every one of the dollies shown here share a potentially fatal flaw. None of them appear to have a jack screw for lifting to dolly off of the wheels for imaging. Imaging on a wheeled dolly will almost certainly limit the quality of the results. Another potential problem is the use of wood, which isn’t mechanically very rigid. Wood can work for a small light scope but just don’t touch anything while the scope is running. Remember that at 1”, everything (even metal) is made of rubber! That means that you should use the most rigid materials possible.

You can see the roll out platform that I built for my 20” scope here:

https://www.astrobin.com/dlko5b/N/

I was concerned that this setup might ring as well, but it turned out to work really well. The entire rig weighed around 700 lbs but it took two fingers to roll it out and it provided sub-arcsecond stability. It was also extremely easy to polar align. I didn’t realized it when I designed it but the arrangement of the jack-screws provided near orthogonal polar alignment capability in altitude and azimuth. Using a PoleMaster, I could have PA done in about 5 minutes and a 70 point full sky model done 10 minutes later.

John

I have some of these machine tool casters https://www.amazon.com/Homhoo-Adjustable-Anti-Vibration-Workbench-Equipment/dp/B0B62J1ZRV/ref=sr_1_3?crid=2KGC0PKXG03NX&keywords=3"+level+casters&qid=1691275728&sprefix=3+level+caster%2Caps%2C181&sr=8-3 which I think will suffice for a rig that weighs maybe 150lbs tops.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

John Hayes:

Every one of the dollies shown here share a potentially fatal flaw. None of them appear to have a jack screw for lifting to dolly off of the wheels for imaging. Imaging on a wheeled dolly will almost certainly limit the quality of the results. Another potential problem is the use of wood, which isn’t mechanically very rigid. Wood can work for a small light scope but just don’t touch anything while the scope is running. Remember that at 1”, everything (even metal) is made of rubber! That means that you should use the most rigid materials possible.

You can see the roll out platform that I built for my 20” scope here:

https://www.astrobin.com/dlko5b/N/

I was concerned that this setup might ring as well, but it turned out to work really well. The entire rig weighed around 700 lbs but it took two fingers to roll it out and it provided sub-arcsecond stability. It was also extremely easy to polar align. I didn’t realized it when I designed it but the arrangement of the jack-screws provided near orthogonal polar alignment capability in altitude and azimuth. Using a PoleMaster, I could have PA done in about 5 minutes and a 70 point full sky model done 10 minutes later.

John

Mine lifts the wheels off the ground.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

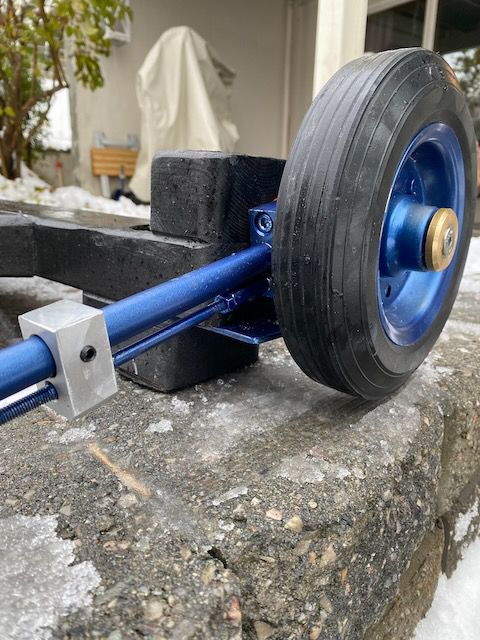

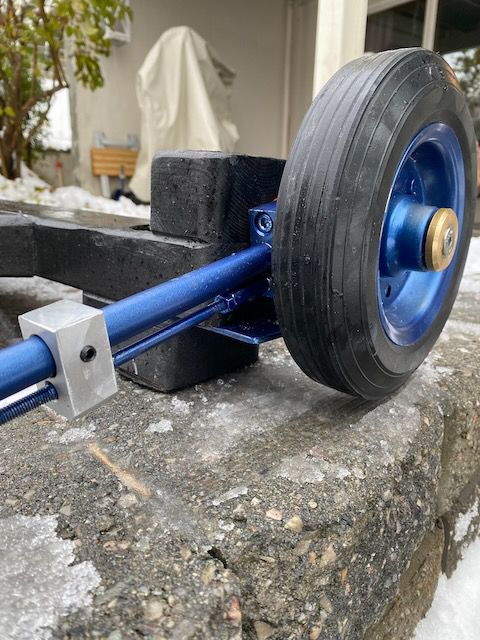

A little late to the party but here is my so called Dolly.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

I use these piano mover casters. Just roll my rigs out of the garage about 50' to my driveway. Removing the casters and placing the legs in their exact position on the driveway makes polar alignment very easy with the polemaster. This way I never disassemble my rigs. Cheers

https://www.uline.com/Product/Detail/H-5245/Dollies/Leg-Dolly-2-Casters?pricode=WB1828&gadtype=pla&id=H-5245&gad_source=1&gclid=CjwKCAiA-bmsBhAGEiwAoaQNmtg_AUukbfA8Qqkl9c-o7Larow9dx-HeZvNNgBWuejVG4H4rizi7phoCggIQAvD_BwE |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Monty Chandler:

I use these piano mover casters. Just roll my rigs out of the garage about 50' to my driveway. Removing the casters and placing the legs in their exact position on the driveway makes polar alignment very easy with the polemaster. This way I never disassemble my rigs. Cheers

https://www.uline.com/Product/Detail/H-5245/Dollies/Leg-Dolly-2-Casters?pricode=WB1828&gadtype=pla&id=H-5245&gad_source=1&gclid=CjwKCAiA-bmsBhAGEiwAoaQNmtg_AUukbfA8Qqkl9c-o7Larow9dx-HeZvNNgBWuejVG4H4rizi7phoCggIQAvD_BwE

Hey Monty,

Those would work great however, my driveway is all rock, no concrete. Hence the much larger rubber wheels on the wagon, it rolls over the rocks much easier.

Good choice though for those that have concrete to roll on. My old house had a concrete driveway and that would have been great for the casters.

Thanks for sharing,

Clear Skies,

DJ

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

I first made a jack up dolly, but found it to be very sensitive to wind, so I came up with a solution to lift the wheel up and lower the dolly on the ground

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

@Roy Hagen Excellent idea Roy..

Love the ingenuity and making it work as needed.

Good job.

DJ

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

@Roy Hagen Excellent idea Roy..

Love the ingenuity and making it work as needed.

Good job.

DJ

Thanks, DJ👍

It is as far as I can see, a very stable dolly

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Great thread!

I've owned one of the old JMI carts and a Scopebuggy. The JMI was pretty good, but the Scopebuggy was not so great for me. Both could be wobbly. The Scopebuggy dumped my C11 twice. I caught it once, and the other I didn't.

My C11 is away for repair at Celestron, and I don't plan to use it again until I can get a good mobile platform for getting it in and out the backdoor.

Love that pier cart @Roy Hagen!

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Great thread!

I've owned one of the old JMI carts and a Scopebuggy. The JMI was pretty good, but the Scopebuggy was not so great for me. Both could be wobbly. The Scopebuggy dumped my C11 twice. I caught it once, and the other I didn't.

My C11 is away for repair at Celestron, and I don't plan to use it again until I can get a good mobile platform for getting it in and out the backdoor.

Love that pier cart @Roy Hagen!

Yeah, both of those would have been too wide for my application and yeah, so sorry to hear about the C11 being dumped, that would be awful to deal with. Hope you get that fixed and back into action soon.

Clear skies,

DJ

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

I built this one. I learned to weld to make it. All of the parts are listed in the post. It has been a real back saver. You can make it to fit you own dimensions.

https://astrob.in/a98azj/B/ |

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

Great thread!

I've owned one of the old JMI carts and a Scopebuggy. The JMI was pretty good, but the Scopebuggy was not so great for me. Both could be wobbly. The Scopebuggy dumped my C11 twice. I caught it once, and the other I didn't.

My C11 is away for repair at Celestron, and I don't plan to use it again until I can get a good mobile platform for getting it in and out the backdoor.

Love that pier cart @Roy Hagen!

@JayRuhMe Thanks, my friend. I do not claim any copyrights on this one🤩, I just have to make something to fasten the pier to the dolly.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

I went a different way. The problem I have is to come out the back door I need to traverse both a step, and two doors. Come out the front (say the garage) where there is room and I have to make my way over quite rough ground with a dolly. So....

I take the OTA and counterweights off (the latter more because I worry about their bouncing around damaging the mount than weight). I move the mount and tripod with a handtruck customized to be wide enough to reach two legs, and narrow enough to go through the doors, with wheelbarrow tires that are really large to handle rough ground:

The black pillows cushion it when I tip it back, the strap (visble going between the RA axis supports) is just a big piece of velcro to help tip everything back. Notice the spikes.

When in place, I have a second handtrick with egg crates. The top one holds all the counterweights (I put a wooden bottom in to re-inforce since it may carry over 100 pounds for some OTA's), the middle has two power supplies, the bottom is empty and just to save me bending over. This also has big tires but those are stock tires, not modified.

I carry the OTA's out by hand, I do not trust them bouncing around. Finally (next image)....

The spikes on the tripod go into pavers that remain in the ground, where I drilled holes that are NOT large enough for them to go all the way down. This means they are held by the circumference of the spike not the tip, and self center in the paver. By doing this (and not moving the mounts alt/az) I end up polar aligned withing about 2-5 arc minutes provided it is the same OTA as last time (if I change OTA just the weight difference plus mounting hardware difference may put me half a degree or so off).

Landing this close to polar aligned saves a lot of time, since I am just tweaking it not starting degrees off and potentially having to actually rotate the tripod (though the AP mount has a really large Az range so that's rare).

Carrying out a C11 to place on it is my worst part, not because it is the heaviest (my SVX152T is about the same), but because it is really awkward to hold and place in the saddle. But all the rest -- the mount, counterweights, tripods, etc. are just a matter of rolling and putting in place. It's not as nice perhaps as a dolly that I could roll the whole way, but I image in SW Florida, so half the year that grass is a muddy mess, I'm not sure how well a fully assembled (and thus VERY heavy) setup would roll on any reasonable sized tires. I'd almost certainly need a powered one to keep from getting stuck in the mud or wearing myself out.

Think "Monster Truck" dolly. Not exactly my idea of imaging.

But this works. I can be set up or torn down in 20 minutes easily (+/- taking flats).

Linwood

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

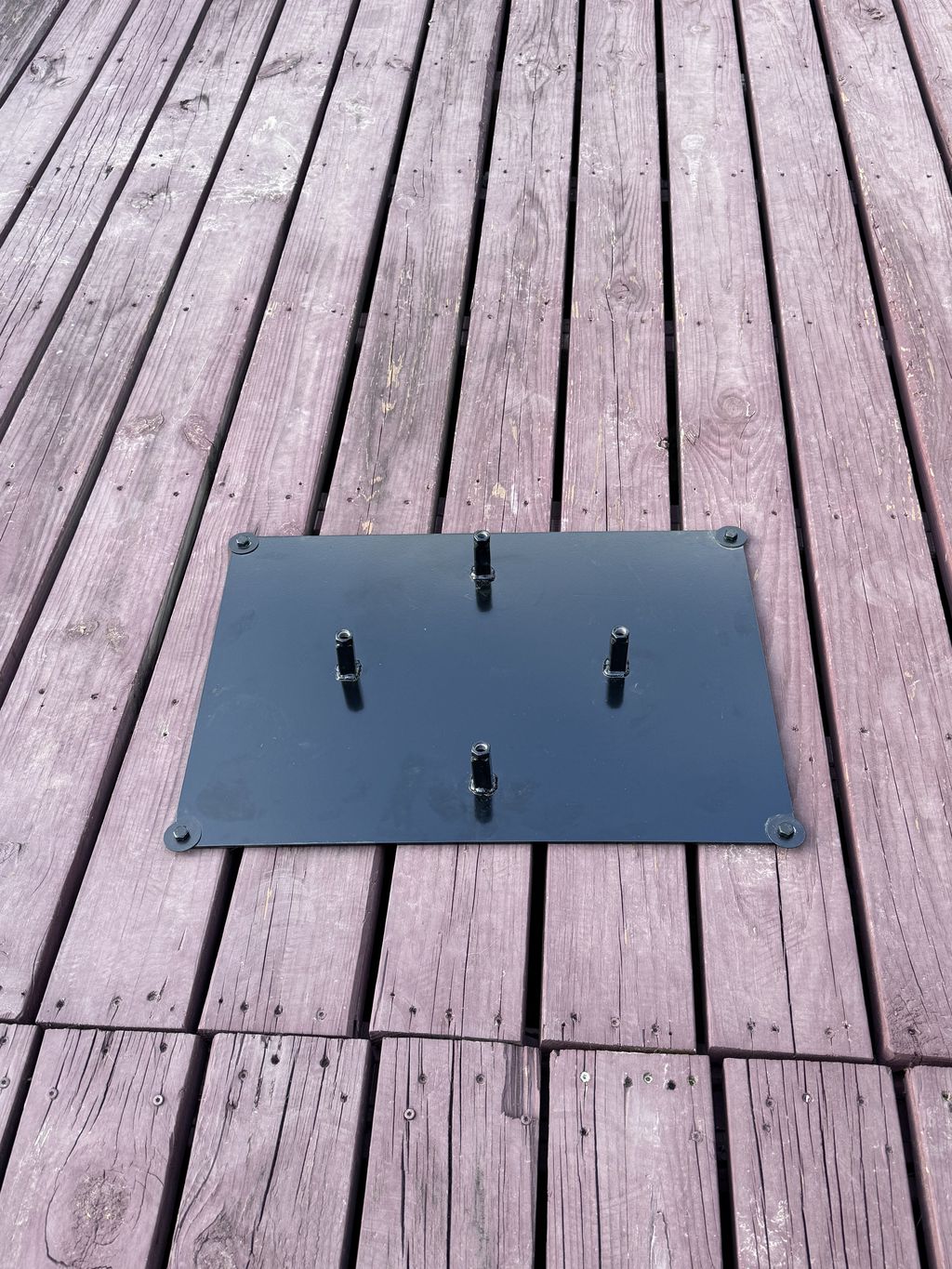

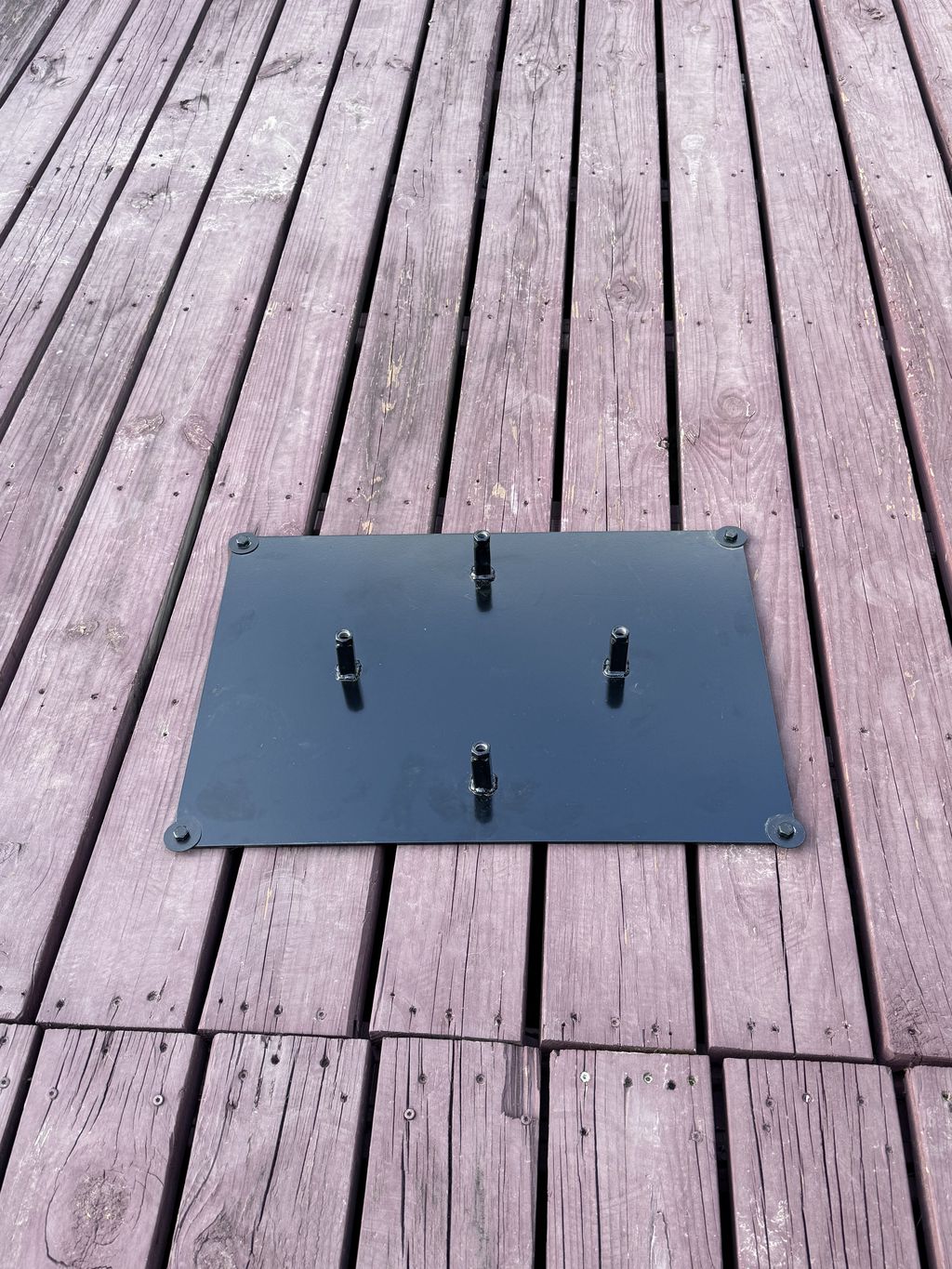

This thread inspired me to go and solve for some problems that myself and others have had when it comes to moving large telescopes around. Below is my beta/POC version of my first Mobile Pier Cart. I plan to start my own little business and sell this and a few other models I'm still designing.

Details are as follows:

- 6-inch, hollow, square pier. This allows you the option to fill with sand for vibration dampening.

- 1/4-inch plate on all parts

- Pneumatic casters on sealed hubs

- 25-inches wide, 40-inches long. Fits easily through standard interior home doors.

The deck/slab plate can be mounted to a wooden deck or concrete patio slab. The cart rolls over the deck plate and screws down into the deck plate to lock the cart in place. This will help in maintaining polar alignment and prevent any accidents from happening where the scope may tip over. I am planning 3 models to support scopes of various sizes.

The problems that this cart solves for me are:

- Stability in imaging

- Ease of setup as it never has to be torn down.

- Rolls very smoothly across any surface.

- Allows me the convenience of having a pier and being able to move my equipment indoors nightly.

First night imaging with a C11/Hyperstar on a AM5 I was averaging .5 RMS in light winds. A second night with 20+ MPH gusts put me at .8 average. I'm happy so far and have testing this week at 2800mm focal length. We'll see how it does there.

|

You cannot like this item. Reason: "ANONYMOUS".

You cannot remove your like from this item.

Editing a post is only allowed within 24 hours after creating it.

You cannot Like this post because the topic is closed.

to create to post a reply.